Large and small, impressive buildings and structures shape our world – and not just in a literal sense. They largely influence how we live, work, learn, play, and travel. But behind each construction project are individuals who face real challenges and dangers to their health and safety daily.

And it’s not just the immediate, visible risks like falls or machinery accidents. There are other tolls exacted on workers’ health that often unfold slowly over time, such as exposure to dust, chemicals, extreme noise, and physical demands that eventually wear on the body.

It’s for these reasons that managing health and safety in construction has called for a little remodeling itself over recent years.

In this blog, we’ll cover the main health risks in construction, the best practices for managing them, the role specialized providers play, and how to choose the right one.

Key Takeaways on Occupational Health in Construction

Managing occupational health and safety in construction aims to mitigate the physical health, mental health and environmental health risks through the following 8 key best practices:

- Strictly abiding by OSHA Regulations

- Conducting Regular Risk Assessments

- Providing Health and Safety Training

- Ensuring Proper Use of Personal Protective Equipment (PPE)

- Involving Employees in Health and Safety Programs

- Engineering Out the Risks

- Implementing Administrative Controls

- Using Technology to Manage Health Risks

Read on to learn how to effectively implement these strategies and safeguard your construction workforce.

What are the Main Occupational Health Risks in Construction?

The risks in construction work are indeed many, impacting workers in various ways. But to tackle them, we need to understand the different types. Broadly, they can be grouped into three primary categories.

Physical Health Risks

The nature of construction demands a high level of physical exertion. While physical exertion is, of course, considered a good thing in most cases, the often-demanding conditions lead to over-exertion, and generally not using the correct form. The resulting toll this takes on the body can manifest in numerous ways. Musculoskeletal disorders, such as back pain, joint injuries, and repetitive strain injuries, are commonplace due to the frequent lifting, bending, and carrying involved in the job. These conditions often develop gradually, making them easily overlooked until pain and disability set in. Not to be forgotten are the less obvious but equally significant risks like noise-induced hearing loss and hand-arm vibration syndrome.

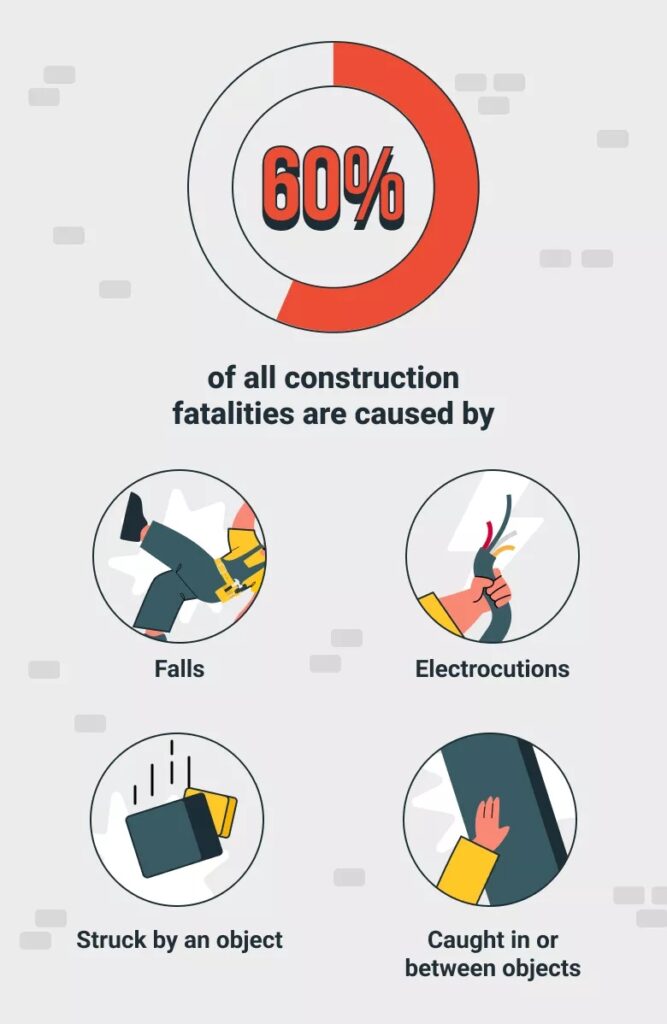

Then we also need to consider hazards like falls, slips, trips, struck-by incidents, caught-in or-between scenarios, and electrocutions that are ever-present, often leading to serious injuries.

Mental Health Risks

Construction sites can be tough on the mind as well. A growing body of research indicates that the construction industry has a much higher prevalence of anxiety, depression, and stress-related illnesses compared to other sectors. This has largely been linked to factors such as job insecurity, long hours, tight deadlines, often isolated conditions, and the transient nature of projects.

Compounding this, the stigma surrounding mental health in construction is still very much present, making it difficult for workers to seek help. Unfortunately, it often culminates in a higher prevalence of substance abuse disorders and suicide.

Environmental Health Risks

Workers are exposed to various hazardous substances, including dust, silica, asbestos, and other chemicals. These can cause respiratory problems, lung diseases, and even cancer. Extreme weather conditions, such as heat and cold, can lead to heatstroke, hypothermia, and other health problems. Even the sun, a constant companion for outdoor work, can cause skin damage and heat stress over time. Conversely, extreme cold can carry risks such as hypothermia, trench foot, and other cold-related complications.

While the list of occupational health hazards in construction may seem exhaustive and impossible to tackle, many best practices and strategies have emerged that are putting positive change in motion for the industry.

Best Practices and Strategies for Managing Occupational Health in Construction

Construction safety management is a large undertaking, and it can be difficult to ensure all bases are covered. Here we detail some of the best practices and top strategies for managing health risks in the construction industry.

1. Strictly abide by OSHA Regulations

OSHA (Occupational Safety and Health Administration) is the key figurehead for creating, maintaining, and monitoring a baseline for construction site safety, providing key guidelines for the most common potential hazards. These commonly include, but are certainly not limited to:

- Fall Protection: Designed to prevent falls from heights, which are a leading cause of fatalities in construction.

- Hazard Communication: Requires employers to inform workers about the hazardous chemicals they may be exposed to on the job and provide training on safe handling practices.

- Scaffolding: Addresses the safe erection, use, and dismantling of scaffolding.

- Trenching and Excavation: Sets standards for protecting workers from cave-ins and other hazards associated with excavations.

All health and safety management systems should align with, if not exceed, OSHA regulations, not only to avoid legal repercussions and penalties but also as a moral obligation to take worker welfare seriously.

Beyond OSHA, it’s equally important to consider and comply with local and international health and safety standards. These often provide additional layers of protection and may address specific regional concerns.

2. Conducting Regular Risk Assessments

As is the changeful nature of construction work, new hazards emerge at every stage of a project. Here, a little proactivity goes a long way. Regular risk assessments act as a map, highlighting potential hazards and outlining the measures needed to prevent them. Managing occupational health risks in construction generally involves systematically:

- Identifying Hazards: Carefully examine the worksite, tools, materials, and tasks to pinpoint potential sources of harm, both obvious and less apparent.

- Assessing Risks: Determine the likelihood of each hazard occurring and the potential severity of its consequences. This helps prioritize which hazards need immediate attention. Factors such as the frequency and duration of exposure, the number of workers exposed, and the availability of existing control measures should all be considered.

- Implementing Control Measures: Based on the risk assessment, appropriate measures need to be put in place to eliminate or, at minimum, reduce the identified risks. This could involve modifying work processes, providing safety equipment, or improving training and supervision.

- Consistently Reviewing and Updating: These assessments should be performed regularly, especially when new tasks are introduced, work conditions change, or after any incident. The frequency can vary depending on the project’s nature and the risk involved.

3. Providing Health and Safety Training

With new materials, tools, technologies, and regulations that come into play regularly, keeping up to date with these requires more than just an initial induction. Ongoing training is the tool that allows workers and supervisors alike to constantly update and refresh their understanding of health and safety protocols. Relying on Industrial Athletic Trainers can potentially help ensure proper training, but comprehensive onsite healthcare is what really makes a difference in promoting physical well-being and injury prevention as a whole.

- Identify Needs: Before rolling out a training program, it’s important to understand what the existing knowledge gaps are. This can be done through regular reviews of incident reports, observing workers on-site, and by simply talking to them about their experiences. The goal is to pinpoint areas where training can have the biggest impact.

- Develop Programs: When putting these programs together, keep in mind that they should be relevant to the specific tasks and roles within the construction site. Programs should be engaging and interactive, utilizing a mix of theoretical and practical elements to keep workers interested and provide a deeper context for real-world scenarios.

- Deliver Training: Schedule training sessions regularly, especially when new hazards or equipment are introduced. Make training accessible and convenient for all workers by offering flexible timings and diverse formats (e.g., online modules, on-site workshops). Utilize experienced trainers who can effectively communicate information and answer questions.

- Evaluate and Update: The effectiveness of any training program should be regularly assessed through feedback from workers, quizzes, and observations. This feedback then informs the updates and modifications to the training program, ensuring it remains relevant and effective.

4. Ensuring Proper Use of Personal Protective Equipment (PPE)

Whether it’s a hard hat guarding against falling objects or steel-toed boots protecting feet from heavy machinery, PPE adds a very important layer to your safety management system. However, it all comes down to proper usage.

- Select Appropriate PPE: The type of PPE required should be determined by a risk assessment of the worksite and tasks (as outlined above), as different hazards will necessitate different protective measures.

- Train Employees on PPE Use: Workers must be thoroughly trained on how to properly use, wear, and maintain it. Training should cover the limitations of each type of PPE and the procedures for reporting any damage or defects.

- Monitor PPE Usage: Regular inspections and supervision ensure that PPE is being used consistently and correctly.

- Maintain and Replace PPE: Regularly inspect all PPE for wear and tear. Damaged or worn-out PPE should be repaired or replaced to ensure its continued effectiveness.

5. Involving Employees in Health and Safety Programs

When it comes to health and safety, many times a boots-on-the-ground perspective can reveal the most practical solutions. Drawing on their insights and tapping into their experiences can uncover hazards that might otherwise go unnoticed.

Some strategies to get the ball of collaboration rolling might include:

- Form Safety Committees: Creating committees that include employee representatives allows for a diversity of viewpoints and a more thorough examination of safety concerns. This inclusive approach not only brings a wider range of hazards to light but also empowers workers, making them more likely to adhere to safety protocols.

- Encourage Feedback: This could be through anonymous suggestion boxes, regular safety surveys, or dedicated feedback channels. The idea is to make it easy for employees to voice their concerns and share their ideas for improvement without fear of judgment.

- Regular Safety Meetings: These meetings serve as a forum for sharing information, discussing incidents, and brainstorming solutions. By involving employees in these discussions, they have a greater sense of ownership in the project overall, while in conjunction, companies can ensure that safety policies and procedures are relevant and effective.

6. Engineering Out the Risks

Engineering controls focus on making physical changes to the workplace to lessen hazards. These controls are often preferred because they remove the hazard or reduce exposure at the source, rather than relying on worker behavior.

- Ventilation Systems: These can remove dust, fumes, and other air pollutants from the work environment, protecting workers’ lungs.

- Noise Barriers: These can absorb or deflect sound, reducing noise levels and the risk of hearing damage.

- Dust Suppression Methods: These can include water sprays or vacuum systems that capture dust before it becomes airborne, safeguarding against respiratory problems.

7. Implementing Administrative Controls

Sometimes, a shift in how work is organized can make a substantial difference. Administrative controls, such as the following, change the way work is performed to reduce or eliminate exposure to hazards.

- Work Rotation: By regularly switching between tasks, workers get a break from repetitive motions and extended exposure to a single hazard. Rotating between physically demanding activities and lighter duties can prevent muscle strain and fatigue.

- Shift Planning: Smart scheduling can limit the duration of exposure to hazards. Scheduling noisy work during periods when fewer people are present can minimize the number of workers exposed to loud noise levels.

- Health Surveillance Programs: Regular check-ups can help spot early signs of health problems, allowing for timely intervention. For instance, regular hearing tests for those frequently exposed to noise can identify early hearing loss, while lung function tests can monitor respiratory health in workers exposed to dust.

8. Using Technology to Manage Health Risks

Digital advancements have found their way into the industry and are starting to show promise in offering new ways in monitoring and controlling health risks in construction:

- Telemedicine: Workplace telemedicine can be particularly beneficial for construction sites in remote locations, where access to immediate medical attention might be limited. Through virtual consultations, workers can receive diagnoses, treatment recommendations, and even prescriptions, reducing the need for time-consuming trips to clinics or hospitals.

- Wearable Technology: Fitness trackers and other wearable devices can monitor workers’ heart rate, activity levels, and sleep patterns, providing insights into their physical health and potential fatigue. Some advanced wearables can even detect falls or other dangerous incidents.

- Monitoring Systems: Environmental monitoring systems can track air quality, noise levels, and other potential hazards, allowing for early detection of risks and prompt intervention.

Enlisting the Help of Specialists Providers

While the responsibility for health and safety in construction falls squarely on the shoulders of employers, many find that bringing in specialists is an invaluable source of support, expertise, and burden alleviation. However, selecting the right provider is a decision that warrants careful thought.

Here’s what to bear in mind:

Understand Your Options

What kind of specialist care do you need? Do you need onsite medics? A full occupational health clinic? Or an injury management-centered solution? This is where all those careful risk assessments we mentioned earlier might help. But be careful to assess your needs accurately to avoid unnecessary expenditure or gaps in coverage.

Experience and Expertise

Does the provider possess in-depth knowledge of occupational health hazards specific to construction? Do they have a proven track record in working with construction companies? These are questions you should be asking potential providers. Look for a provider who not only understands the regulations and best practices but also has practical experience implementing them in real-world construction scenarios.

Accessibility and Responsiveness

How easy is it to get in touch with the provider? Are they responsive to your inquiries and concerns? In the go-go-go world of construction, timely communication and support are essential. Choose a provider who is readily available and can promptly address any health or safety issues that arise.

Tailored Solutions

Does the provider offer solutions that can be customized to your company’s specific needs and risks? A one-size-fits-all approach rarely works in construction. A good provider will take the time to understand your specific needs and tailor their services accordingly.

Cost-Effectiveness

Though cost is a consideration, it should not be the sole deciding factor. A provider who offers excellent value might not be the cheapest but can save you money in the long run by preventing costly accidents, injuries, and legal issues.

Accreditation and Qualifications:

Is the provider accredited by relevant health and safety bodies? Do they adhere to industry standards and regulations? Ensuring the provider is qualified and compliant can give you peace of mind and ensure that your workers receive the highest quality of care.

Conclusion

In the end, it’s plain to see that health and safety in the construction industry is under construction itself. While there’s no quick fix, the ongoing shift toward whole employee health is starting to pay off.

However, even with the best preventative measures in place, injuries can still happen. Responding promptly and effectively is where a provider specializing in injury management can be instrumental. At JobSiteCare, we have developed solutions designed to streamline the injury management process, ensuring that workers receive timely care and return to work safely and efficiently. If you’d like to learn more, contact us today.

Frequently Asked Questions:

How do you manage occupational health in construction?

Occupational health is managed by identifying and controlling workplace hazards, promoting worker well-being, and complying with legal requirements.

What is the role of management in occupational health and safety?

Management provides leadership, resources, and commitment for a safe and healthy workplace. They set policies, enforce standards, and ensure everyone’s participation in health and safety efforts.

What are the main health risks in construction?

The main construction health risks are falls, exposure to harmful substances (e.g., asbestos, silica, lead), noise-induced hearing loss, musculoskeletal disorders, and mental health issues due to stress.

What are the consequences of non-compliance with health and safety regulations in construction?

Non-compliance can lead to injuries, illnesses, fatalities, legal penalties, financial losses, project delays, and damage to a company’s reputation.

What to expect from an occupational health service provider?

An occupational health service provider generally offers services such as health assessments and monitoring, treatments, and preventive programs to maintain and improve worker health.