In manufacturing, risks are not just possible—they’re inevitable.

From sudden equipment breakdowns to supply chain bottlenecks and safety hazards, even a single issue can derail your timelines, inflate budgets, and compromise worker safety. Managing these variables while ensuring smooth operations often feels like walking a tightrope without a safety net.

But here’s the good news: with the right strategies, these risks can be identified, mitigated, and even transformed into opportunities for improvement.

In this article, we’ll break down the most common risks in the manufacturing industry, explore their potential impact, and provide actionable strategies to keep your projects on track and your workforce safe.

What are the Risks in Manufacturing Projects?

Manufacturing projects involve multiple moving parts—equipment, labor, materials, and supply chains—all working in sync. However, this complexity comes with significant risks.

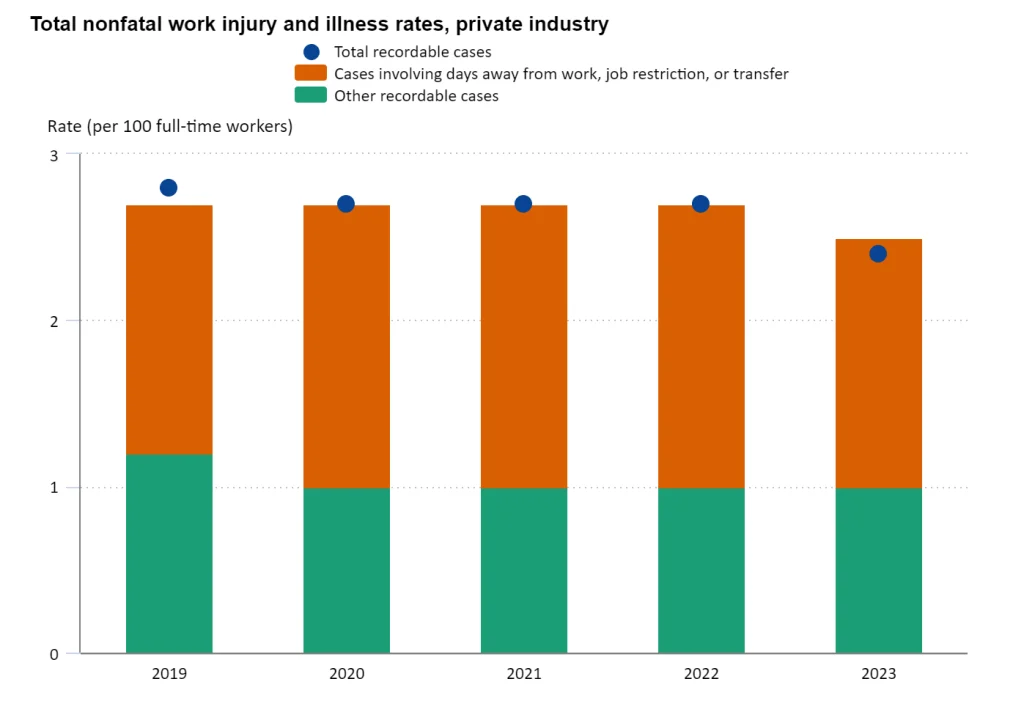

According to the National Safety Council, manufacturing has one of the highest injury rates, with over 400,000 workplace injuries reported annually in the US alone. This can quickly drive the cost of workplace injuries to hundreds of thousands of dollars for employers.

Let’s take a closer look at the 9 key risks in the manufacturing sector:

Machinery and Equipment Hazards

Machinery is an indispensable part of manufacturing operations, but it also poses serious risks if not managed carefully.

For instance, a conveyor belt or high-powered press can cause severe injuries if safeguards aren’t in place. Also, if operators are not fully trained to handle equipment, the chance of accidents increases even more.

The solution? Ensuring regular maintenance thorough inspections and comprehensive training programs that teach employees how to interact with machinery. This creates a safer workplace, minimizes downtime, and increases productivity—benefiting both employees and the organization.

Chemical and Environmental Risks

Handling dangerous chemicals requires constant vigilance. Toxic exposure during handling or improper storage can lead to respiratory issues, skin irritation, or long-term health problems for workers. Beyond employee health risks, spills or leaks can contaminate the environment and lead to legal fines.

To mitigate these risks, you should have robust storage protocols, provide workers with proper personal protective equipment (PPE), and instruct everyone on safe handling procedures. Additionally, spill response plans and environmental monitoring systems can prevent small issues from escalating into major disasters.

Supply Chain and Resource Constraints

In manufacturing, supply chain disruptions can bring even the most well-planned projects to a standstill. If you experience delays in raw materials, unexpected transportation challenges, or unpredictable logistics, this can unlock a whole set of other problems and potentially lead to losing millions of dollars.

To minimize these risks, you can:

- Diversify your supplier network

- Maintain buffer inventories

- Leverage real-time tracking tools

Additionally, building strong relationships with suppliers can help you adapt to unforeseen challenges and keep your projects on track.

Workforce and Labor Market Challenges

With 51% of manufacturing workers aged 45-65 and fewer young people entering the industry, the talent gap in the manufacturing industry is growing. This leaves the sector with 10 million vacant job openings worldwide.

Additionally, poorly designed workstations can lead to ergonomic issues like repetitive strain injuries, further increasing turnover and reducing productivity.

To attract diverse talent, you can implement strategies like:

- DEI programs and flexible work arrangements

- Ergonomic assessments and tailored workstation designs to prevent injuries

- Initiatives like employee health programs

Regulatory and Compliance Risks

Navigating various regulations and compliance requirements imposes a whole set of new challenges.

Standards like OSHA (Occupational Safety and Health Administration) focus on workplace safety, while ISO (International Organization for Standardization) certifications address quality management and environmental practices. Failing to comply with these regulations can lead to hefty fines, operational shutdowns, and reputational damage.

To stay compliant, you should conduct regular audits, thorough documentation, and proactive employee training. Also, resources like OSHA’s official website can help you stay updated.

Financial and Market Risks

This involves market fluctuations from inflation and rising operational and material costs to the possibility of recession. The effect? Shrinking profit margins and added layers of uncertainty.

These pressures are compounded by fluctuating material costs and shifting consumer demands, which can derail budgets and timelines.

To mitigate these risks, you can adopt flexible pricing strategies that adjust to market conditions and invest in contingency planning. For instance, diversifying suppliers and renegotiating contracts can buffer against sudden cost spikes and ensure you can adapt quickly to an ever-changing economic landscape.

Slips, Trips, and Falls

Slips, trips, and falls are a leading cause of workplace injuries in manufacturing, often resulting in significant downtime and costly compensation claims.

55% of these incidents are caused by spilled liquids or oils, uneven or cluttered flooring, and poorly lit work areas, which create unsafe conditions for employees navigating busy production floors.

Minimizing these risks starts with:

- Implementing regular housekeeping protocols to keep walkways clear and dry

- Using slip-resistant flooring

- Ensuring employees wear proper footwear designed for manufacturing environments

- Conducting frequent safety audits

Technological Implementation Risks

Adopting new technologies like IoT devices or cloud-based systems can revolutionize manufacturing, but these innovations also come with their own set of risks. Poorly planned rollouts can disrupt workflows, while employees may have trouble adapting to unfamiliar tools.

To avoid these obstacles, you should develop phased implementation plans that include comprehensive training for staff and pilot testing to identify potential issues early. This can help you harness the benefits of new technologies while maintaining smooth production processes.

Sustainability Challenges

For many industries, including manufacturing, sustainability is no longer optional—it’s a core expectation tied to Environmental, Social, and Governance (ESG) standards.

Companies face pressure to minimize their environmental impact through practices like waste reduction, energy efficiency, and adopting smart building technologies. However, integrating sustainable processes often requires significant upfront investment and changes to longstanding workflows.

Achieving these sustainability goals while keeping up with operational demands can feel daunting, but you can start by taking small, deliberate steps. For example, implementing waste management systems or switching to energy-efficient equipment reduces both costs and carbon footprints. By prioritizing sustainability, you can also position yourself as a leader in a more eco-conscious marketplace.

Why is Risk Assessment Essential in Manufacturing Projects?

Manufacturing risk assessment can help you achieve better manufacturing safety. It’s essentially an investment in a safer, more resilient workplace.

To assess risks effectively, you need to:

- Identify potential risks: Pinpoint hazards across all areas of operations, from equipment malfunctions to supply chain disruptions. This ensures no risk is overlooked.

- Evaluate likelihood and impact: Assess the probability of each risk occurring and the severity of its consequences so you can prioritize the most critical issues.

- Rank risks by priority: Categorize risks to allocate resources effectively, addressing the most urgent threats first.

- Monitor and update assessments regularly: Manufacturing environments evolve, and so do the risks. Continuously updating assessments keeps safety measures relevant and effective.

5 Key Challenges Employers Face in Mitigating Manufacturing Risks

Manufacturing is inherently risky, and while employers aim to create safe environments, certain challenges make risk mitigation a complex task. Let’s explore these in more detail:

1. Balancing Safety Investments with Cost Pressures

Employers often struggle to allocate sufficient budgets for safety initiatives, such as modernizing equipment, offering extensive training, or improving ergonomics.

But cutting costs can actually lead to more injuries down the line and even more serious financial consequences. For example, a report by the National Safety Council shows that workplace injuries cost US based employers over $167 billion in 2022 alone.

Solution: Prioritize safety as an investment rather than a cost. Upfront spending in this case can prevent accidents and save money by reducing downtime and workers’ comp claims.

2. Workforce Engagement and Compliance

Getting employees to consistently adhere to safety protocols and actively participate in risk mitigation efforts can be difficult. However, non-compliance can lead to an increase in incident occurrences. For example, workers who do not use PPE are 3 times more likely to get injured than those who do.

Solution: Foster a safety-first culture by making safety training interactive, providing incentives for compliance, and using tools like peer observation programs to encourage accountability among team members.

3. Managing Complex and Evolving Regulations

Not staying updated and compliant with changing regulations can result in penalties, legal issues, and reputational harm. OSHA fines for serious violations can reach $16,131 per incident, with repeated violations costing even more.

Solution: Use compliance software, partner with safety experts, and schedule routine audits to stay ahead of changes. Proactive planning ensures you’re not caught off guard by regulatory shifts.

4. Addressing Ergonomic and Repetitive Strain Risks

Manufacturing roles often involve repetitive tasks and awkward postures, leading to injuries like carpal tunnel syndrome or chronic back pain. In the long term, this can lead to decreased productivity, increased worker absences and even employee turnover.

Solution: Conduct ergonomic assessments of employee workstations and equipment to minimize strain. Consider assistive tools like adjustable tables, anti-fatigue mats, or lifting equipment to reduce repetitive stress.

5. Having Limited Onsite Injury Management Resources

Many manufacturing facilities lack immediate access to onsite healthcare. In turn, this leads to delayed care, increased recovery time, and a negative effect on employee morale.

Solution: Consider partnering with injury management services to ensure workers receive timely care. Immediate access to medical expertise keeps employees healthier and operations running smoothly.

6 Best Practices for Health & Safety Risk Management in Manufacturing

Effective health and safety risk management is the backbone of any successful manufacturing operation.

Below are the best practices for risk management in manufacturing projects:

1. Implementing the Preliminary Hazard Analysis (PHA)

PHA is an invaluable tool for identifying and mitigating risks before they escalate. Think of it as a structured approach to proactive safety that helps employers prevent costly downtime and improve operational efficiency.

Key steps in conducting a PHA:

- Identify potential hazards: Evaluate equipment, processes, and environments for potential risks.

- Rank by severity and likelihood: Prioritize hazards that pose the greatest risk to your workforce and operations.

- Develop mitigation strategies: Design actionable steps to reduce or eliminate high-priority risks.

2. Regular Maintenance and Inspections

Machinery malfunctions are a leading cause of workplace accidents, but they’re often preventable.

To ensure safety, you can create a maintenance schedule tailored to your machinery and train staff to conduct regular inspections. Implementing this type of preventative care is always more cost-effective than emergency repairs.

3. Workforce Training and Onsite Safety

Empowering your team with knowledge is key to a safe workplace. That’s why it’s worth investing in comprehensive safety training. This gives you peace of mind that employees understand protocols, recognize hazards, and respond appropriately to incidents.

Partnering with services like JobSiteCare for tailored training programs and onsite medical solutions can boost employee confidence and reduce recovery times.

4. Supplier Diversification

Relying on a single supplier can leave you vulnerable to disruptions. Whether it’s delayed shipments or material shortages, dependency on one source exposes you to more risks.

To avoid any unforeseen bottlenecks, you should work with multiple suppliers, especially during global supply chain disruptions.

5. Technology and Automation

Modern technologies can prevent operational risk in the manufacturing industry.

For instance, sensors can alert teams to overheating machinery or irregular pressure levels, allowing for swift response to critical situations. Also, investing in technology not only improves safety but also enhances operational efficiency.

6. Establishing a Risk Management Culture

Operational risk management in manufacturing works best when it’s a shared priority. Building a culture that values safety starts with leadership actively promoting and modeling effective risk management and risk mitigation behaviors.

To do that, you can foster open communication, recognize employees who uphold safety standards, and make safety training an ongoing initiative.

The Role of a Reliable Injury Management Partner in Mitigating Risks

In manufacturing, where risks are part of daily operations, having a reliable injury management partner can make all the difference.

Here’s how this kind of partnership can help you improve your risk mitigation strategies:

Immediate Response to Workplace Incidents

When an accident occurs, every second counts. Whether it’s a deep laceration from machinery or a chemical exposure incident, onsite medical teams can deliver immediate care, minimizing the severity of injuries and reducing downtime.

Ultimately, quick interventions ensure workers receive the right treatment without delays, leading to better recovery outcomes and fewer disruptions.

Preventative Health and Risk Assessments

Onsite injury management partners conduct regular health screenings and ergonomic evaluations to identify risks before they lead to injuries.

For example, assessing workstation setups can prevent repetitive strain injuries, while monitoring workers’ health helps flag early signs of potential problems, keeping your workforce healthy and productive.

Training and Safety Advocacy

Equipping your workforce with knowledge of safety procedures automatically decreases the chances of workplace incidents.

Onsite medical professionals can educate employees on using PPE correctly, responding to emergencies, and following safety protocols. These training sessions empower workers to stay vigilant and proactive, reducing preventable incidents across the board.

Compliance Support and Long-Term Safety Planning

Navigating complex health and safety regulations, like OSHA standards, can be overwhelming. But injury management partners can take this weight off your shoulders and ensure compliance by conducting regular audits. They can also provide guidance on maintaining adherence to evolving regulations while helping you establish long-term safety goals.

Conclusion: Proactive Risk Management for Manufacturing Success

Managing risks in manufacturing projects is the foundation for a safer, more efficient and profitable workplace. To achieve this, you can adopt best practices and leverage advanced tools like PHA.

Ready to take your risk management strategy to the next level? JobSiteCare offers comprehensive workplace injury solutions tailored to the manufacturing industry. Contact us today to learn how we can help protect your workforce and keep your projects on track.

FAQs on Risks in Manufacturing Projects

1. Why is manufacturing a risky industry for workforces?

Manufacturing combines high-powered machinery, fast-paced workflows, and complex processes, making it one of the riskiest industries. Employees often work in hazardous environments with heavy equipment, chemicals, and tight deadlines, all of which increase the potential for accidents and injuries.

2. What are the health and safety risks of manufacturing?

The primary risks include machinery-related injuries, exposure to hazardous materials, repetitive strain injuries, and slips or falls. In addition, long hours and stressful environments can lead to fatigue, increasing the likelihood of mistakes and accidents.

3. How to mitigate manufacturing risk?

Start by conducting regular risk assessments to identify potential hazards. Implement safety protocols, provide ongoing training, and equip employees with proper PPE.

Leveraging technology, such as automation and monitoring systems, can further reduce risks by minimizing human error and ensuring compliance with safety standards.

4. What is the role of management in ensuring manufacturing safety?

By prioritizing clear communication, enforcing safety policies, and leading by example, leaders set the tone for the entire workforce. Regular safety audits, employee feedback sessions, and investments in safety training also ensure that risks are continually addressed and minimized.