Keeping everyone safe at work is a core responsibility for any business, big or small. However, moving beyond mere compliance to actively create an environment that prevents workplace injuries is a challenge many still face.

Each year, over 4.1 million workers are seriously injured on the job, and tragically, more than 12 workers die each day—amounting to over 4,500 fatalities a year. The repercussions of these injuries are magnified when incidents go unrecognized, unreported, or uncorrected, impacting not just the well-being of employees but also the operational efficiency, cost of workplace injury management and morale of the entire organization.

In this blog, we will outline practical tips and strategies for preventing workplace injuries, emphasize the crucial roles of management and staff in this process, and discuss the key components that should be included in any effective workplace injury prevention plan.

Key Takeaways

Protecting your workforce from injuries entails the following key practices:

- Create a safety management system

- Perform health screenings early and often

- Provide education and training

- Enhance situational awareness

- Implement 24/7 safety monitoring

- Strengthen team collaboration

- Support mental health initiatives

Workplace Injury Prevention Tips and Strategies

1. Create a Safety Management System

A formalized workplace safety management system offers a structured framework for risk identification and workplace injury management. Understanding how and who benefits most from workplace safety regulations can raise awareness and improve safety outcomes. Develop a system with well-defined policies, responsibilities, and procedures, ensuring that everyone in your organization understands their role in safety. This could include:

- Leadership Involvement: Secure visible, active commitment from senior management. Their actions demonstrate the importance of workplace safety and set the tone for the entire organization.

- Define Clear Roles and Responsibilities: Establish accountability at all levels of the organization, outlining who is responsible for planning, implementing, and monitoring each aspect of the safety system.

- Incorporate Industry Standards and Best Practices: Tailor your SMS to your specific workplace needs while aligning with recognized industry standards (e.g., OSHA, ISO 45001). This adds credibility and ensures your system meets widely accepted benchmarks.

- Establish Communication Channels: Implement open, two-way communication on safety-related topics. Encourage employees to report hazards, participate in safety discussions, and provide feedback for improvement.

- Document Your System: Develop a comprehensive safety manual or handbook with clearly defined policies, procedures, and best practices. This manual becomes a living document that is reviewed and updated regularly.

2. Perform Health Screenings

Regular health screenings facilitate early detection of potential health issues before they lead to serious issues and can help you take informed, preventive action. To integrate this successfully, you should consider:

- Establishing a Baseline: Encourage employees to undergo initial health screenings to establish a baseline of their health conditions. This allows for better tracking of any changes and for early detection of potential health risks that might be exacerbated by workplace hazards.

- Proactive Identification: Schedule regular health screenings tailored to the specific risks present in your workplace. If employees handle chemicals, include screenings for respiratory function and chemical exposure levels. If heavy lifting is common, consider physical exams focused on musculoskeletal health.

- Collaborating with Health Partners: Partner with occupational health clinics or medical providers like JobSiteCare to develop customized screening programs aligned with the needs of your workforce. These experts can help determine the appropriate screening frequency and the most relevant tests for your industry.

3. Provide Advanced Education and Training

Traditional safety training often focuses on rule memorization instead of underlying principles. To go beyond this, educational programs should explain the “why” behind safety measures, demonstrating the real-life consequences of specific actions or inactions. This type of in-depth understanding helps employees make informed decisions and actively contribute to a safe working environment. Some specific strategies could include:

- Scenario-Based Learning: Present realistic workplace situations where they must analyze potential hazards, make safety decisions, and understand the consequences of their choices. This immersive training creates a deeper understanding of safety principles.

- Gamification: Incorporate elements of gamification into training, such as points, badges, and leaderboards, to increase engagement and motivation. Interactive formats make safety training more enjoyable and can improve knowledge retention.

- Role-Specific Training: Not all employees face the same level of risk. Customize education to the hazards encountered by specific job roles. This focused approach ensures employees receive training that’s most relevant to their daily tasks.

- Injury Response Training: It’s important to be prepared for the possibility of injuries despite strong prevention efforts. Establish a clear workplace injury response procedure and train the entire workforce in its execution to ensure the best possible coordinated response.

4. Enhance Situational Awareness

A proactive safety mindset means being constantly alert to potential hazards. Implement programs that teach employees how to continually assess their surroundings for risks, such as:

- Observation Programs: Implement observation programs where trained individuals observe their colleagues at work and provide supportive feedback on safe and at-risk behaviors. This active form of peer assessment promotes real-time awareness and accountability.

- Hazard Mapping: Encourage teams to create hazard maps of their work areas. This visual representation helps everyone identify potential risks and develop solutions collectively.

- Near-Miss Reporting Incentives: Develop an incentive system for near-miss reporting. By rewarding employees for identifying and reporting close calls, you gather valuable data and encourage proactive safety behavior.

5. Implement Real-Time Safety Monitoring

Advanced technologies significantly enhance real-time monitoring capabilities within workplace environments. By investing in devices and systems that track worker health indicators and highlight unsafe conditions, organizations can take swift action to mitigate risks and prevent accidents. Here are some examples of such technologies:

- Wearable Technology: Explore the use of wearable devices to track vital signs like heart rate and fatigue indicators. This data can offer early warnings of potential health concerns or overexertion, helping to prevent on-the-job incidents.

- Environmental Sensors: Deploy sensors to monitor factors like air quality, temperature, noise levels, and the presence of hazardous materials. This allows for immediate detection of unsafe conditions and trigger alerts.

- Utilizing Predictive Analytics: Collect and analyze safety data over time to identify patterns and trends. Employ predictive analytics to forecast potential hazards, enabling targeted preventative measures.

6. Strengthen Team Collaboration

Encourage cooperation on safety matters by creating a collaborative environment where employees across departments take ownership of workplace safety. A few ways to achieve this could be to have:

- Safety Champions Networks: Identify safety leaders from different departments to form a cross-functional team. This network leads by example, champions safety initiatives, and acts as a resource for other employees.

- Cross-departmental Incident Investigations: Invite members from various teams to participate in analyzing workplace incidents. This collaborative review leads to a broader understanding of contributing factors and fosters insights into system-wide improvements.

- Shared Safety Metrics: Make workplace safety a key performance indicator (KPI) across all departments. Track and communicate these metrics openly to instill a sense of shared responsibility and accountability.

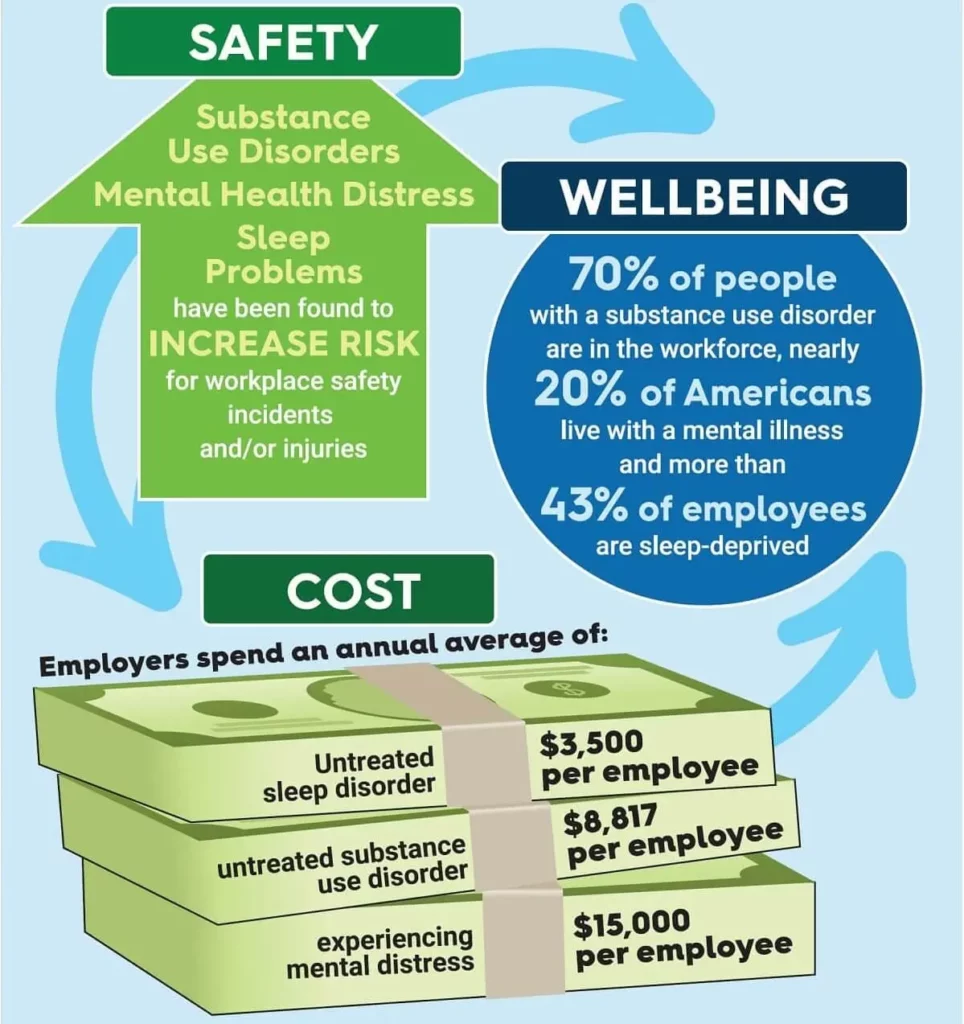

7. Support Mental Health Initiatives

Recognize that mental health is as crucial as physical well-being in preventing workplace injuries. Implement wellness programs that address stress management, burnout prevention, and resilience building. This could include:

- Mindfulness and Relaxation Programs: Provide accessible resources and training sessions on mindfulness techniques, stress reduction, and mental resilience. This helps employees manage daily anxieties and focus their attention.

- Confidential Support: Offer access to confidential counseling or employee assistance programs (EAPs) where employees can receive mental health support without fear of judgment or consequences.

Preventing Workplace Injuries Involves a Collaborative Effort

Management’s Role

Employers hold the primary responsibility for setting and upholding safety standards.

This includes:

- Developing and Enforcing Safety Policies: Create clear, comprehensive safety policies that are regularly updated and enforced. These policies should be accessible to all employees and integrated into daily operations.

- Investing in Safety Training and Education: Provide ongoing training and education that helps employees understand safety protocols and the reasons behind them. Training should be engaging, practical, and tailored to the specific needs of the workplace.

- Providing Proper Equipment: Ensure that all safety equipment is up-to-date, properly maintained, and readily available. This includes personal protective equipment (PPE), safety guards on machinery, and any other tools necessary for safe operations.

- Encouraging Reporting and Feedback: Create a transparent atmosphere where employees are encouraged to report safety issues and concerns in the workplace. Feedback mechanisms should be straightforward, ensuring that employees can freely communicate without fear of negative consequences.

The Workforce’s Role

While employers provide the framework for a safe workplace, employees have an equally important role in maintaining and enhancing this environment.

This includes:

- Adhering to Safety Protocols: Employees must follow the safety rules and procedures established by their employers. This includes using PPE when required, following safe work practices, and attending training sessions.

- Staying Informed and Educated: Employees should seek to understand the risks associated with their roles and the measures in place to mitigate these risks.

- Reporting Hazards and Incidents: Employees should report any unsafe conditions, hazards, or near misses they encounter. Prompt reporting can prevent accidents and injuries, making it a critical component of workplace safety.

- Contributing to a Safety Culture: By demonstrating a commitment to safety, employees can influence their peers and contribute to a culture that prioritizes well-being over shortcuts.

Common Workplace Injuries, Their Causes, and How to Avoid Them

Slips, Trips, and Falls

According to the National Safety Council, slip, trip, and fall incidents rank among the top causes of workplace injuries, often resulting in strains, sprains, and even fractures.

Common Causes: Wet or cluttered floors, uneven surfaces, loose cables, inadequate lighting, and improper use of ladders.

Preventive Measures:

- Maintain tidy and well-lit workspaces.

- Clearly mark uneven surfaces or potential hazards.

- Train employees on proper ladder safety and usage.

- Encourage the use of appropriate, non-slip footwear.

Cuts and Lacerations

Roughly 30% of all workplace injuries involve cuts or lacerations. These injuries range from minor nicks to serious wounds.

Common Causes: Handling sharp tools and equipment without proper training or protection, working with broken or damaged materials, and rushing or working carelessly.

Preventive Measures:

- Conduct training on the safe use of knives, machinery, and other equipment with sharp edges.

- Provide appropriate cut-resistant gloves and other personal protective gear.

- Maintain tools and equipment in good condition, repairing or replacing damaged items promptly.

Overexertion and Repetitive Strain Injuries (RSIs)

Jobs involving repeated motions, heavy lifting, or awkward postures put workers at high risk for back injuries, carpal tunnel syndrome, and other musculoskeletal issues.

Common Causes: Lifting heavy loads without proper technique, poorly designed workstations, sustained awkward postures, and repetitive tasks without sufficient breaks.

Preventive Measures:

- Implement ergonomic principles in the design of workstations.

- Train employees in safe lifting techniques and body mechanics.

- Encourage regular breaks and task rotation to minimize repetitive strain.

- Provide mechanical aids or lifting devices when needed.

Burns

Burns caused by heat, chemicals, or electricity can result in serious and sometimes disabling injuries.

Common Causes: Contact with hot surfaces or flames, spills or splashes of caustic chemicals, faulty electrical equipment, and improper handling of flammable substances.

Preventive Measures:

- Implement clear procedures for handling hot substances and chemicals.

- Provide necessary protective gear (gloves, aprons, face shields) and train in its use.

- Regularly inspect and maintain all electrical equipment.

- Enforce strict protocols for handling and storing flammable materials.

Exposure to Harmful Substances

Exposure to toxic chemicals, gases, or harmful particulates can lead to both acute and long-term health problems, sometimes with delayed symptoms.

Common Causes: Inadequate ventilation, lack of proper respiratory protection, improper handling or storage of chemicals, and accidental spills.

Preventive Measures:

- Clearly label and maintain an inventory of all hazardous substances.

- Provide safety data sheets (SDS) for all chemicals and train employees on their use.

- Ensure adequate ventilation systems in areas where hazardous substances are present.

- Implement strict procedures for cleaning up spills and require appropriate protective gear.

- Provide training on how to recognize and respond to signs of chemical exposure.

Key Components to Bolster Your Workplace Injury Prevention Plan

To truly step-up your efforts, here are some additional proactive components worth considering:

Qualified Onsite Medics

Having qualified onsite healthcare professionals directly on your worksite allows for immediate assessment and treatment of injuries. This minimizes delays in treatment, potentially reducing their severity and improving recovery outcomes. JobSiteCare’s qualified medics provide on-the-ground medical expertise, streamlining care and supporting a safety-first work environment.

Telemedicine-led Expert Physician Access

24/7 access to qualified doctors through telemedicine empowers employees with immediate support, regardless of the time or location of a health concern. This allows for early intervention and guidance on appropriate next steps. JobSiteCare’s network of physicians ensures that expert medical advice is always seconds away.

Job Site Data Analytics

Collecting and analyzing safety data can uncover trends and potential risk areas that might otherwise go unnoticed. This enables you to shift from reactive to proactive safety management by targeting prevention efforts at the root causes of incidents. JobSiteCare’s advanced analytics tools provide insights that empower you to make informed decisions for continuous safety improvement.

Conclusion

Even with the best prevention strategies, injuries can still happen. When they do, JobSiteCare offers an innovative workplace injury solution. Our focus on streamlined processes, expert medical access, and proactive case management ensures your employees receive the best possible care and a smoother return to work.

Frequently Asked Questions

What industries would benefit the most from a workplace injury prevention plan?

All industries stand to benefit from implementing a workplace injury prevention plan, particularly those where physical labor is prevalent, such as construction, manufacturing, healthcare, and logistics. However, even less physically demanding sectors like retail, office environments, and hospitality can significantly reduce risks and enhance employee safety through tailored prevention strategies.

Is workplace injury prevention only recommended for hazardous industries?

While workplace injury prevention is critical in hazardous industries, it’s beneficial for all sectors. Every workplace has potential hazards, whether they involve physical safety, ergonomic risks, or even psychological health. Comprehensive injury prevention plans help mitigate these risks across various environments.

How can employers create a safe work environment?

Employers can ensure a safe work environment by conducting regular safety audits, providing the necessary personal protective equipment, and maintaining clear safety protocols. Educating employees on these protocols and encouraging a culture of safety further supports a less injury-prone workplace.

What can employers do to prevent musculoskeletal injuries?

To prevent musculoskeletal injuries, employers should focus on ergonomics, providing employees with tools and workstations that support natural posture and minimize strain. Regular training in proper lifting techniques and the use of mechanical aids can reduce physical exertion. Also, promoting breaks and physical exercises that relieve repetitive stress can help manage these injuries effectively.

How can employers encourage employee engagement in injury prevention?

Employers can boost employee engagement in injury prevention by involving them in safety planning and decision-making processes. Regular feedback mechanisms, safety committees, and incentives for safe behavior are effective ways to keep employees invested in workplace safety.

Is it always possible to prevent work-related injuries?

Unfortunately, not. While not all work-related injuries can be completely prevented, many can be avoided through comprehensive safety measures and proactive prevention strategies. However, having a solid workplace injury response procedure is crucial for managing incidents that do occur. Leveraging expert support, such as services from JobSiteCare, ensures that injuries are handled effectively and recovery processes are optimized, minimizing the impact on both employees and the business.