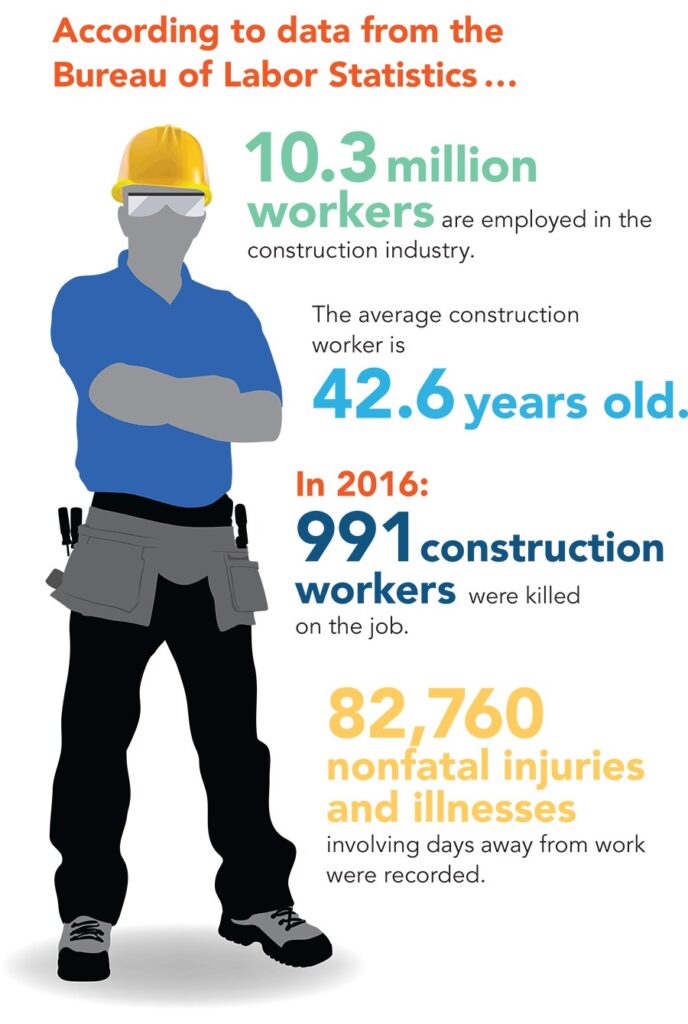

The construction industry is a key link within both our economic and livelihood chains. Unfortunately, however, it holds a less desirable distinction: it is one of the most hazardous sectors for workers. In 2021 alone, over 169,000 construction workers suffered injuries requiring medical care, with nearly 40% of such incidents resulting in lost workdays. The industry also recorded over 1,000 fatalities, accounting for 21% of all worker deaths in the U.S.

These numbers demand notice and an urgent call to action by means of a more effective and proactive approach to construction safety management. Meaning, safety and occupational health in construction is more than hard hats and high-vis vests. It’s about smart planning, forward-thinking, and a shift in mindsets to maintain the careful balancing act of keeping projects on track and making sure everyone gets home safe at the end of the day.

This blog will look at just why this is so important, as well as the strategies and best practices on how to effectively mitigate incidents from occurring.

What is construction safety management?

Construction site safety Management is the process of planning, organizing, and controlling activities to prevent accidents and injuries on construction sites. Such a vital process normally relies on a Safety Management System (SMS) that carefully defines the policies, procedures, and practices that guide the way in which safety in the workplace is dealt with.

What are the Main Objectives?

Proper management aims to achieve several important outcomes:

Reducing Incident Rates: The primary aim is to reduce the frequency of accidents, injuries, and death at construction sites as much as possible.

Complying with Regulations: Construction projects are subject to several safety regulations and standards, as mandated by governing bodies. The safety management aspect here safeguards that the project conforms to the laws, preventing legal consequences or fines.

Enhance Productivity: Effective construction safety and health management creates a conducive environment for better productivity by helping workers focus on their tasks with far less apprehension for their well-being. Additionally, when employees feel safe, they are more likely to be engaged and motivated. As a result, productivity and general job satisfaction increase.

Reputation Protection: A good reputation increases trust in business. Consequently, clients and partners are more likely to invest in and collaborate with companies that value the safety of their employees.

Costs Control: Accidents can lead to significant financial losses due to medical expenses, project delays, and potential lawsuits. Effective safety management helps prevent or at least decrease the severity of these costly incidents. In fact, OSHA found that companies with effective safety programs generally experience between a 20% to 40% reduction in injury and illness costs.

Improving insurability: A good safety record can often translate to lower insurance premiums. Insurance providers generally offer lower premiums to companies with a proven track record of safety.

Who Bears the Responsibility?

Safety in the workplace is, and should be, a shared responsibility. While a company’s leadership team or construction site safety officer certainly sets the tone, every individual on site has a role to play. There are some duties that tend to be associated with certain roles:

- Management: They are responsible for establishing and enforcing safety policies, providing resources for safety programs, and ensuring that all workers receive proper training.

- Supervisors: They run the day-to-day operations, making sure work is done safely and workers comply with safety rules.

- Workers: They are responsible for following safety rules and regulations, using personal protective equipment (PPE) correctly, reporting hazards, participating in safety training, etc.

- Construction Safety Managers: They work to develop and deploy safety programs, conduct all inspections/audits of the job site, ensure they are compliant with established requirements, complete incident investigations when needed, and provide guidance on how businesses can better respond if an unplanned event is ever faced.

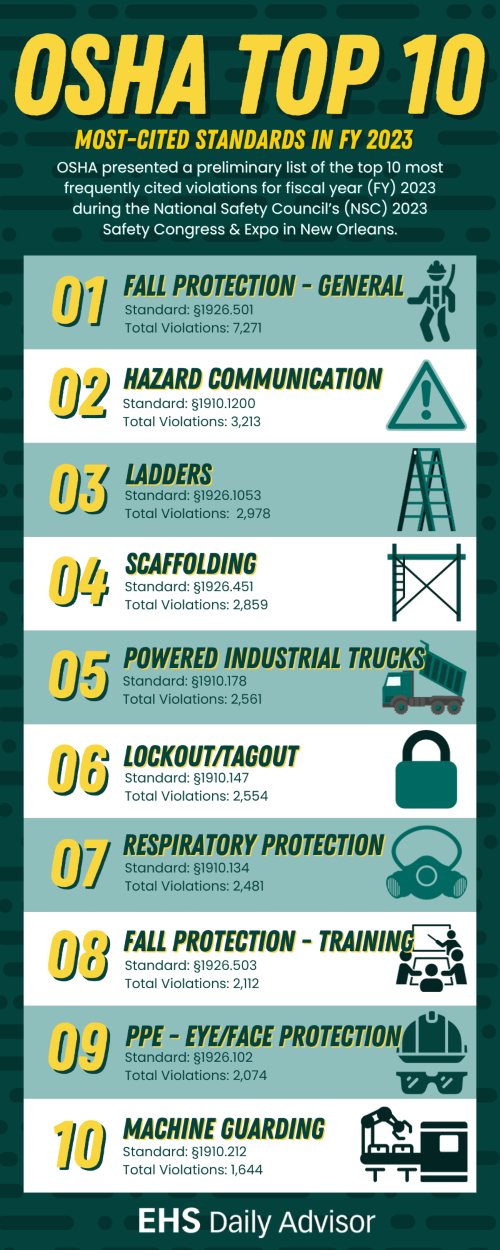

Understanding OSHA Construction Safety Standards

OSHA is the main overseer that sets and enforces workplace safety standards in the United States. They address broad categories of hazards and activity areas, thereby establishing a framework for construction site safety.

General Duty Clause

The cornerstone of OSHA regulations is the General Duty Clause. It requires employers to provide a workplace free from recognized hazards likely to cause serious injury or death. Even if there is no specific standard for a particular hazard, the General Duty Clause requires all employers to take measures, which they determine are reasonable and necessary.

Fall Protection (29 CFR 1926.501)

- Guardrails: When working at heights of 6 feet or more, guardrails must be installed and have a top rail height of 42 inches, plus or minus 3 inches, above the working level. They should withstand a force of 200 pounds applied within 2 inches of the top edge.

- Safety Nets: Safety nets must be installed as close as practicable under the working surface and be strong enough to withstand a 400-pound bag of sand dropped from the highest point of the work area.

- Personal Fall Arrest Systems: If guardrails and safety nets are not feasible, personal fall arrest systems (PFAS) must be used. These include full-body harnesses, lanyards, and anchor points capable of supporting 5,000 pounds per worker.

Hazard Communication (29 CFR 1926.59)

- Written Hazard Communication Program: Employers must have a written program outlining how they will identify and evaluate hazards, provide training, and communicate information about hazardous chemicals to workers.

- Safety Data Sheets (SDS): Employers must have an SDS for each hazardous chemical on site, accessible to workers, and include information on the chemical’s properties, hazards, and safe handling procedures.

- Labels: Containers of hazardous chemicals must be labeled with the chemical’s name, hazard warnings, and the name and address of the chemical manufacturer or importer.

Scaffolding (29 CFR 1926.451)

- Construction: Scaffolds must be built with sound, rigid materials and designed by a qualified person.

- Load Capacity: Each platform must support its own weight plus four times the maximum intended load without failure.

- Access: Safe access to scaffolds must be provided, such as ladders, stair towers, or ramps.

- Fall Protection: Workers on scaffolds 10 feet or higher must be protected from falls by guardrails, safety nets, or PFAS.

Respiratory Protection (29 CFR 1926.103)

- Respirator Selection: Employers must select respirators appropriate for the hazards present and ensure a proper fit for each worker.

- Training: Workers must be trained in the proper use, maintenance, and limitations of their respirators.

- Medical Evaluation: Workers must be medically evaluated to ensure they are fit to wear a respirator.

Electrical Safety (29 CFR 1926 Subpart K)

- Grounding: Electrical systems and equipment must be grounded to protect against electrical shock.

- Wiring Methods: Appropriate wiring methods must be used, such as rigid metal conduit or electrical metallic tubing, and wiring must be protected from damage.

- Equipment Installation: Electrical equipment must be installed and maintained according to the manufacturer’s instructions and applicable codes.

Personal Protective Equipment (PPE) (29 CFR 1926 Subpart E)

- Head Protection: Hard hats must be worn when there is a potential for objects falling from above, accidental head contact, or electrical shock.

- Eye and Face Protection: Safety glasses, goggles, or face shields must be worn when there is a risk of flying particles, molten metal, liquid chemicals, acids, or caustic liquids.

- Hand Protection: Gloves must be worn when there is a risk of cuts, abrasions, punctures, chemical burns, or thermal burns.

- Foot Protection: Safety-toed shoes or boots must be worn when there is a risk of foot injuries from falling or rolling objects, or objects piercing the sole.

Ramifications of Non-Compliance

Failure to comply with these set out standards can result in damaging repercussions, including:

- Citations and Fines: OSHA can issue citations to employers for unsafe practices that may result in substantial penalties.

- Work stoppages: In cases of severe violations, OSHA can halt work on a project until the safety hazards have been corrected.

- Legal Liability: Non-compliance can lead to lawsuits from injured workers or their families, resulting in significant financial damages.

- Reputation Damage: Violations can ruin the reputation of a company leading to loss of clients and skilled workers.

Implementing Construction Safety Management Practices

Assess Current Safety Conditions

Every jobsite has specific conditions: data center safety is different from energy safety. Begin by performing a thorough risk assessment to identify potential hazards. In most cases, this would involve inspecting the site for unsafe conditions, assessing the potential impact of these hazards, and determining the likelihood of their occurrence. This information can then be used to prioritize risks and develop improvement strategies. Remember to regularly update assessment findings to reflect any changes in the work environment or project scope.

Draft Safety Policies and Procedures

From there, you can begin to set out safety policies and procedures tailored to your construction site’s unique situation. These documents should outline clear guidelines for safe practices, detailing the responsibilities of each worker and the specific protocols for various tasks. Make sure these policies comply with local, state, and federal safety regulations. Distribute copies of these policies to every employee and ensure that they can be accessed for reference easily.

Workforce Training and Education

Design and deliver full-fledged safety training programs for the entire staff. They should be trained in general safety practices, site-specific facility hazards, and emergency procedures. Workers must know how to properly utilize safety gear and be well informed about the hazards inherent in their jobs. Provide ongoing refresher training and updated safety standards/procedures.

Monitor Compliance and Conduct Inspections

Regularly monitor compliance with safety policies and procedures through scheduled and unscheduled site inspections. Use checklists to ensure all aspects of the safety program are being followed. Document any violations and take corrective actions promptly. These inspections help maintain a high level of safety awareness and identify areas for improvement.

Provide PPE

Ensure that all workers have access to appropriate PPE and understand how to use it correctly. This includes items such as helmets, gloves, safety glasses, and harnesses. Regularly inspect and maintain PPE to ensure it remains effective and replace any damaged or worn-out equipment immediately.

Establish Emergency Response Plans

Develop step-by-step emergency response plans for incidents that may occur. This refers to procedures in case of fire, medical emergency evacuation, hazardous substance spills, heat safety issues and natural disasters. Regularly drill your employees on these plans so they are familiar with them and able to act quickly in the event of an emergency. Additionally, ensure your team is well-versed in fire safety in the workplace to enhance overall safety.

Encourage Reporting and Feedback

Build a culture in which employees are not afraid to report safety issues, or indeed accidents themselves, for fear of the consequences. Create an easily understood reporting process and make sure every report receives due attention and is investigated thoroughly. Use the feedback to continuously improve safety practices and address any issues promptly.

Review and Improve

Continuously review and improve safety practices by analyzing incident reports, inspection findings, and feedback. Look for trends and recurring issues to identify areas that require more focus and attention.

Conclusion

Construction safety management demands vigilance as risks can evolve daily. But by prioritizing prevention through comprehensive protocols, extensive training, and an unyielding dedication to safety refinement, businesses can notably diminish workplace incidents.JobSiteCare’s construction site medical services further enhance these efforts by providing immediate, expert care in the event of an incident, minimizing downtime, and maximizing worker well-being. Contact us today to find out more.

Frequently Asked Questions

What is a safety management system in construction?

A safety management system (SMS) in construction is a proactive process to identify, assess, and manage hazards on a job site. It’s a structured way to prevent accidents by putting controls in place before incidents occur.

What are the basic functions of a construction safety management system?

A safety management system typically involves hazard identification, risk assessment, control measures, and communication. It ensures that everyone on site understands the potential dangers and knows how to mitigate them.

What is OSHA safety management?

OSHA safety management refers to a series of guidelines and regulations set forth by the Occupational Safety and Health Administration, a U.S. federal agency responsible for workplace safety. These guidelines outline best practices and standards that companies must follow to ensure worker safety.

What does a safety officer do in construction?

A safety officer or safety construction manager oversees the implementation and effectiveness of the safety management system. They conduct inspections, investigate accidents, and train workers on safety procedures, with the aim being to prevent accidents and promote a safety-conscious culture on the construction site.